Our customers put a lot of effort into optimizing their battery plates for maximum efficiency and performance. BTS machines give them the ability to turn those designs into reality, automating repetitive processes to reduce costs and improve their batteries' quality.

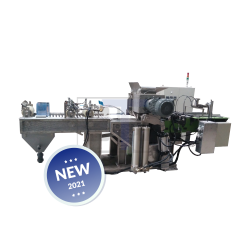

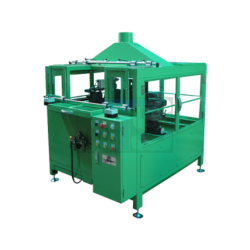

Currently, our plate manufacturing line includes gravity casting machines (compatible with most common car and motorcycle battery plate designs), single- or double-side pasting machines and drying tunnels. A comprehensive range of plate cutting, brushing and stacking machines — custom-made in close cooperation with our customers, with an emphasis on safety and cleanliness — ensures a perfect finish, helping to avoid short-circuit and other conditions that may surface during the COS and assembly line.

Currently, our plate manufacturing line includes gravity casting machines (compatible with most common car and motorcycle battery plate designs), single- or double-side pasting machines and drying tunnels. A comprehensive range of plate cutting, brushing and stacking machines — custom-made in close cooperation with our customers, with an emphasis on safety and cleanliness — ensures a perfect finish, helping to avoid short-circuit and other conditions that may surface during the COS and assembly line.

Battery plate manufacturing